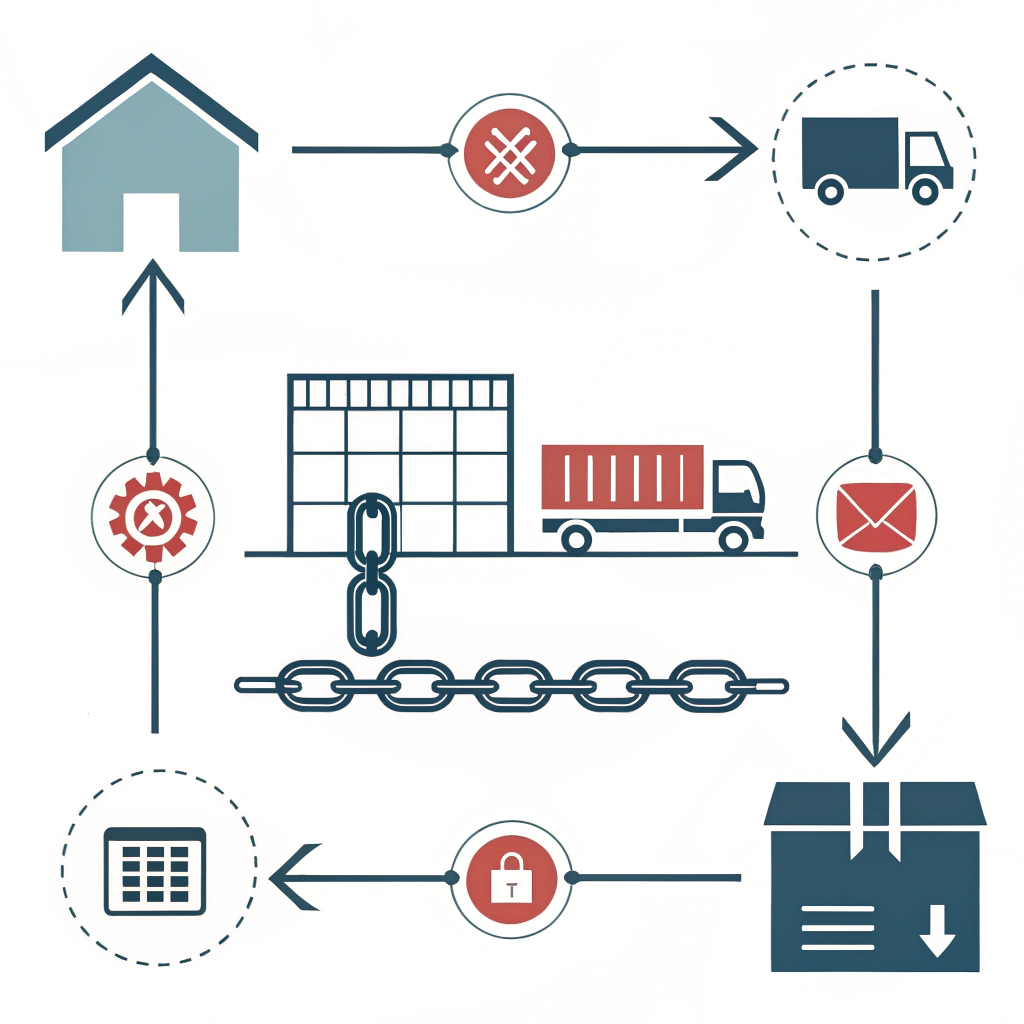

Quick Answer: Integrated logistics support from warehouse to customer hinges on seamless coordination between warehousing, transportation, and order fulfillment. Understanding each link in this chain is crucial for enhancing supply chain efficiency, reducing costs, and improving customer satisfaction.

In today’s fast-paced global market, an efficient logistics support system is a fundamental requirement for companies aiming to stay competitive. For supply chain managers and logistics directors, understanding how warehousing solutions, inventory management, and transportation intricately connect offers the key to streamlining operations and optimizing distribution strategies. In this article, we dive deep into the journey that goods make from the warehouse to the customer, outlining the common challenges, integration methods, and best practices that transform end-to-end logistics into a competitive asset.

Warehousing and logistics are tightly intertwined. Warehousing provides the physical storage space for goods and equips companies with the ability to manage inventory effectively. Once inventory is stored safely, sophisticated inventory management systems monitor stock levels, support consolidation shipping, and ensure products are ready for fast and accurate order fulfillment. The journey is then completed by robust transportation and last-mile delivery1 solutions that ensure products reach the end customer efficiently. This end-to-end process is not siloed—every stage impacts the others.

- Warehousing Solutions: Efficient storage facilities that are often integrated with advanced handling systems.

- Inventory Management: Systems that track stock levels and handle the dynamic nature of inventory across multiple locations.

- Transportation Management: Coordination of freight forwarding, inland trucking, and even air or ocean shipping to drive products to their final destination.

- Order Fulfillment & last-mile delivery1: The final stretch, where consolidation shipping and streamlined logistics support guarantee timely delivery.

Despite advancements in technology, many companies still face significant hurdles in ensuring a smooth journey from warehouse to customer:

- Fragmented Systems: Disconnected processes can result in data silos, where warehousing, transportation, and inventory management do not communicate effectively. This often leads to delays and increased operational costs.

- Inefficient Routing: Poor planning in freight forwarding or last-mile delivery impedes timely delivery and can diminish the customer experience.

- Capacity Constraints: Limited warehouse space or transportation resources can bottleneck operations, especially during peak demand periods.

- Inventory Inaccuracy: Inaccurate stock information due to manual errors or outdated systems can lead to overstocking or stockouts.

- Regulatory Compliance: Different regulatory environments in regions such as the US, Europe, and China require constant vigilance and adaptation, making consolidated logistics more complex.

To better understand the transformation from warehouse to customer, we break down the process into five main stages:

| Stage | Description | Key Considerations |

|---|---|---|

| Inward Logistics | Receiving and inspecting goods; includes customs brokerage and documentation | Accuracy in documentation and timely clearance |

| Storage & Inventory Management | Proper warehousing and continuous monitoring of stock levels | Efficient layout, real-time inventory tracking |

| Order Processing | Consolidating orders, picking, and repacking as needed | Minimizing handling errors |

| Transportation Management | Managing multiple shipping modes: air, ocean, and ground delivery | Coordination between freight forwarders and trucking carriers |

| Order Fulfillment & last-mile delivery1 | Final leg of delivery ensuring customer satisfaction | Optimized routes, real-time tracking |

Each stage is interlinked, and inefficiency in one area can cause cascading delays and increased costs.

To overcome these challenges, companies can adopt a series of systematic improvements. Here’s a clear pathway to bolstering your logistics support system:

Investing in an integrated Supply Chain Management (SCM)2 system can consolidate data from warehousing, transportation, and inventory management. Such systems provide real-time insights, helping managers forecast demand, optimize routes, and schedule shipments efficiently.

- Implement RFID3 or IoT Solutions4: Such technologies enable real-time inventory updates and asset tracking.

- Adopt Transportation Management Systems (TMS)5: Automate route planning and shipment tracking to reduce delays and costs.

Rethinking warehouse organization can lead to significant efficiency gains.

- Optimized Layouts: Use data analytics to design warehouse layouts that minimize travel time for pickers.

- Automation: Incorporate automated storage and retrieval systems (AS/RS) to reduce manual handling errors.

- Effective Cross-Docking: Implement cross-docking techniques to expedite the movement of goods without lengthy storage times.

Effective communication between warehouse teams and logistics providers is crucial in bridging information gaps.

- Centralized Control Towers: Establishing a command center that monitors all logistics activities ensures proactive problem-solving.

- Standardized Documentation: Streamline paperwork and use unified systems to reduce errors.

Offering multiple modes of transportation can safeguard against potential disruptions, ensuring that a backup option is always available.

| Mode of Transportation | Benefits | Considerations |

|---|---|---|

| Air Freight | Fast delivery, ideal for urgent shipments | Higher cost, limited capacity |

| Ocean Shipping | Economical for large volumes | Longer transit times, subject to port delays |

| Inland Trucking | Critical for last-mile delivery and consolidation shipping | Routing efficiency and regulatory compliance |

Using historical data and predictive analytics helps in anticipating seasonal demands and potential bottlenecks in the supply chain.

- Key Performance Indicators (KPIs): Monitor KPIs like delivery time, order accuracy, and transportation costs.

- Benchmarking: Compare performance against industry standards and competitors to identify improvement areas.

Consider a mid-sized retail company that faced recurring bottlenecks in its delivery process. The company’s fragmented logistics system resulted in frequent order delays, particularly during peak sales periods. By integrating an advanced SCM system and employing a centralized control tower, the company was able to:

- Reduce warehouse order processing time by 30%

- Improve transportation route efficiency by 25%

- Enhance overall order fulfillment accuracy from 85% to 95%

The transformation not only reduced operational costs but also significantly elevated customer satisfaction. This case study demonstrates how a methodical approach to logistics support bridges the gap between warehousing and customer delivery, ultimately fostering a more agile and responsive supply chain.

- Consolidate Your Logistics Operations: By merging warehousing, transportation, and order fulfillment into one cohesive process, companies can create an environment of continuous improvement.

- Invest in Training: Equip employees with the skills needed to operate advanced technologies and optimize warehouse processes.

- Focus on Sustainability: Utilize energy-efficient solutions and green transportation options that not only cut costs but also align with global sustainability standards.

- Maintain Strong Partnerships: Collaborate with reliable freight forwarders and local transportation providers to build a dynamic logistics network.

- Prioritize Customer Service: Implement communication tools that offer real-time tracking, ensuring customers have visibility and control over their deliveries.

In today’s interconnected world, the journey from warehouse to customer not only encompasses physical movement but also the seamless integration of technology and people. The key to overcoming challenges in logistics lies in adopting an integrated, end-to-end approach that prioritizes transparency, efficiency, and customer satisfaction.

Companies should begin by performing a comprehensive audit of their current logistics processes. Analyze every stage—from receiving goods at the warehouse to the final mile delivery—and identify inefficiencies that could be improved with technology and streamlined operations. Engaging with a trusted logistics partner who understands both the regulatory complexities and the technical nuances of the global market is equally essential.

In summary, refining your logistics support system involves:

- Implementing integrated systems for real-time data and forecasting.

- Optimizing warehouse operations through layout adjustments and automation.

- Enhancing communication channels among diverse logistics stakeholders.

- Leveraging flexible transportation strategies for uninterrupted delivery flows.

- Committing to a continuous improvement mindset that adapts to new challenges and technological advancements.

By focusing on these actions, supply chain managers and logistics directors can transform their operations into a robust, agile, and customer-centric supply network.

What is the relationship between warehousing and logistics?

The relationship between warehousing and logistics is symbiotic. Warehousing serves as the physical space for storing goods and is essential in the logistics chain as it enables efficient inventory management and preparation for transportation.

What are the steps in the logistics process?

The logistics process typically involves multiple interconnected steps including inward logistics, storage & inventory management, order processing, transportation, and order fulfillment. Each step is vital and inefficiencies in any one area can affect overall performance.

What are the three functions of logistic support?

The three primary functions of logistic support are transportation, warehousing, and inventory management. Together, these functions ensure that products are stored efficiently, moved effectively, and delivered to customers in a timely manner.

-

last-mile delivery: Read this article to understand strategies and solutions that optimize the final leg of the delivery process, ensuring that products reach end customers efficiently. ↩ ↩ ↩2 ↩3

-

Supply Chain Management (SCM): Read this article to gain insights into integrated systems that coordinate and manage the entire supply chain, from procurement to delivery. ↩ ↩

-

RFID: Read this article to explore how radio frequency identification technology is used to improve inventory tracking and enhance operational efficiency. ↩ ↩

-

IoT Solutions: Click here to learn about how Internet of Things (IoT) technologies facilitate real-time monitoring and tracking in supply chain operations. ↩ ↩

-

Transportation Management Systems (TMS): Read this article to discover how TMS platforms help optimize route planning, shipment scheduling, and overall transportation efficiency in logistics. ↩ ↩