Quick answer: The five cultural mistakes foreign buyers most often make with Chinese suppliers are 1) treating negotiation as a one‑off price squeeze instead of relationship building, 2) causing loss of face (mianzi1) with blunt feedback and public pressure, 3) negotiating with the wrong level (not the real decision maker), 4) pushing Western‑style deadlines without confirming factory capacity and buffers, and 5) using vague specs and contracts that leave room for interpretation. Fix these by investing in relationship signals, protecting face with indirect yet clear language, mapping decision makers, locking production calendars with buffer time, and issuing bilingual, highly specific POs/contracts with QC and logistics terms.

Problem: Culture gaps quietly cost you weeks and margins

If you negotiate in a Western style—direct, fast, price‑first—you can still place orders. But you’ll pay for it later: unexpected MOQs2, “OK” that means “maybe,” pushed lead times, and quality rework that erodes margin. In China, negotiation is more than a price talk; it is the start of a working system between companies. You are managing incentives, face, and commitment across sales, production, and finance inside the factory.

The good news: a few cultural adjustments reduce risk, shorten lead times, and stabilize quality. Below are the top five mistakes we see most often, why they happen, and practical fixes you can copy‑paste into your next supplier call or WeChat chat.

Why these mistakes happen

- Relationship versus transaction: The Chinese business norm values guanxi3 (relationship capital) as the base for cooperation. A small price today is less important than reliable volume and predictability tomorrow.

- Indirect communication and face: Protecting mianzi (saving face) means avoiding public “no,” blame, and confrontation. Ambiguity can be a politeness strategy.

- Hierarchy matters: Decisions are often centralized. A sales rep may say “yes” to keep momentum, but the owner or plant manager approves pricing, MOQs, and schedules.

- Time perception and buffers: Factories balance many customers and holidays. “OK” can reflect intent, not confirmed capacity. Buffers are built implicitly unless you ask explicitly.

- Variable interpretation: Without precise specs, AQL4, packaging drawings, and clause‑level detail, both sides fill gaps with assumptions.

Mistake 1: Treating price as a one‑off squeeze instead of a relationship

Symptoms

- Price drops fast early, then lead times slide or materials are downgraded.

- MOQ spikes unexpectedly when you reorder.

- Service fades when a bigger customer appears.

Why it happens

When you push only on unit cost, suppliers hedge elsewhere—quality, timelines, or post‑order flexibility. For them, relationship risk is higher than the few cents you win on price.

How to fix it

- Signal commitment: Share a 6–12 month forecast range and lane plan. Even rough numbers help the factory plan materials and labor.

- Trade value for value: Exchange better payment terms or steadier volumes for cost reductions or lower MOQ.

- Stage pricing: Agree a learning‑curve reduction after the first 2–3 lots if defect rate and throughput targets are met.

Fast script you can use

- “We aim to give you predictable monthly orders. If we confirm a minimum of 2 pallets per month for six months, can you reduce MOQ to 1,000 units per SKU and offer a 3% discount from month three?”

Logistics impact

- Forecasts help reserve capacity during Chinese holidays and peak shipping seasons. This reduces last‑minute air upgrades and demurrage.

Mistake 2: Causing loss of face with blunt feedback or public pressure

Symptoms

- After a tough email CC’ing multiple people, responses slow down.

- Supplier agrees verbally, but nothing changes; production becomes “in progress” for weeks.

Why it happens

Public criticism or direct confrontation can damage mianzi. The safer path is to delay, avoid saying “no,” or provide partial answers.

How to fix it

- Move sensitive feedback to a private call; summarize neutrally in writing afterward.

- Use “blame the process,” not “blame the person.” Offer a solution path that lets everyone win.

- Ask “how can we adjust?” instead of “why did you fail?”

Fast scripts you can use

- Private call opener: “We both want on‑time shipments. It seems the plating line was overloaded. What options do we have this week to recover the two days?”

- Written follow‑up: “To align our process, let’s implement pre‑line checks for the next lot. We will review together on Tuesday.”

Quality control alignment

- Tie face‑saving language to specific AQL limits and rework procedures. You stay firm on standards while respectful on tone.

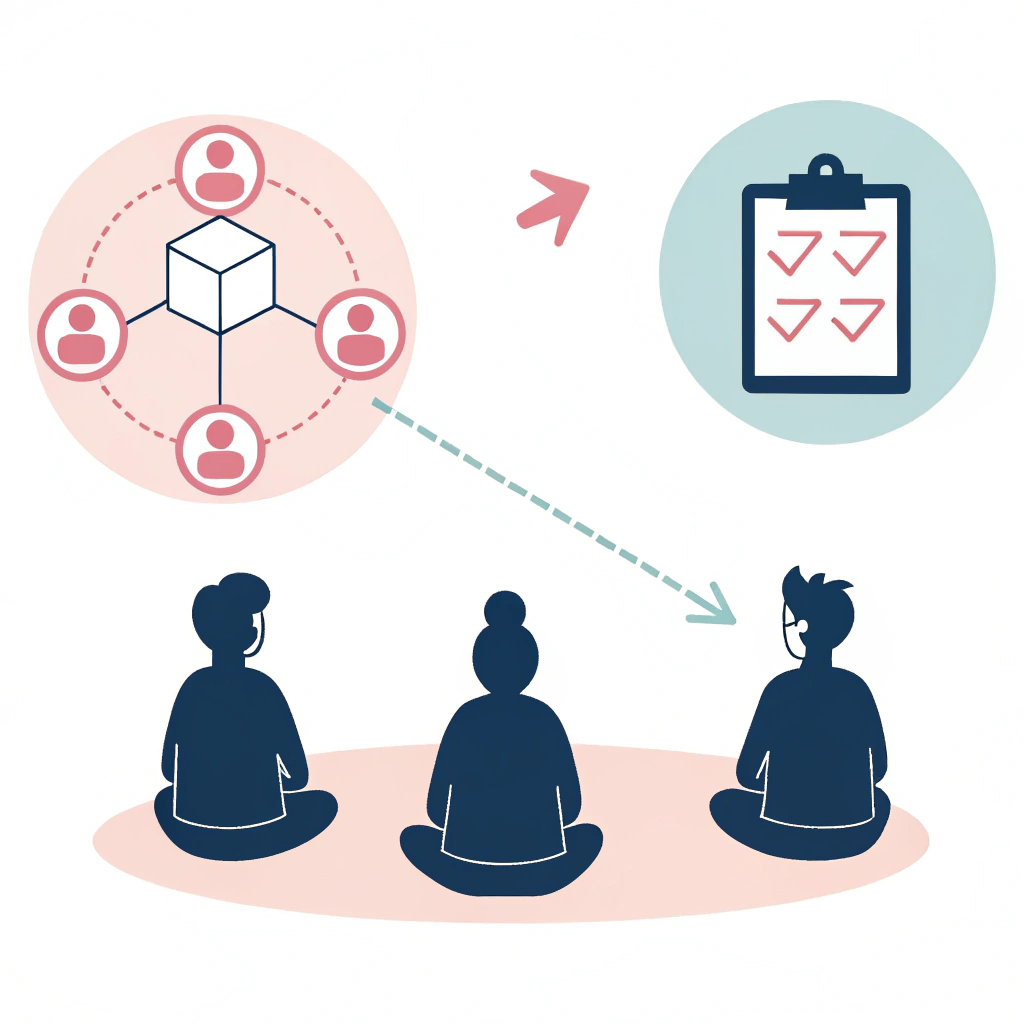

Mistake 3: Negotiating with the wrong level and unclear decision rights

Symptoms

- You agree on pricing and lead time with a sales rep, but the “boss” later changes both.

- Long gaps between messages; approvals “pending.”

Why it happens

Many suppliers keep final decisions with a general manager or owner. Sales wants to keep momentum but cannot commit production slots or override MOQs.

How to fix it

- Map the org: Identify who approves pricing, who controls the production slot, who runs quality, and who signs the chop (company seal).

- Build a WeChat group: Include sales, production planner, QC lead, and finance if payment terms change.

- Confirm authority in writing: “Please confirm who will apply the company chop on the PO and who approves schedule changes.”

Fast scripts you can use

- “To finalize, could we include Ms. Li (production planning) and Mr. Chen (GM) in a 20‑minute call to confirm the ready date and price before we issue the PO?”

- “Who is authorized to stamp the contract and confirm ship window? We want to respect your internal process.”

Mini‑case

A home goods brand kept negotiating with only a sales AE. After adding the plant scheduler and owner to a weekly 15‑minute WeChat huddle, on‑time delivery improved from 74% to 92% over three lots because capacity conflicts were resolved in the meeting instead of after delays occurred.

Mistake 4: Pushing Western‑style deadlines without capacity confirmation and buffers

Symptoms

- Supplier says “OK” but ships five to ten days late.

- Expensive air upgrades to hit your promotion date.

Why it happens

“OK” can mean “we will try.” Chinese holidays, material lead times, and shared subcontractors stretch timelines. If you do not lock a production slot, you are in the flexible queue.

How to fix it

- Lock the slot: Ask for a written “production start” and “finish” date with line assignment if possible.

- Create shared buffers: Add 10–20% time buffer around holidays and during peak months (before Golden Week, before Chinese New Year).

- Confirm logistics backward: Align bookings, cut‑offs, and Incoterms5 so “ready date” ties to vessel or flight schedules.

Helpful timeline structure

| Milestone | Definition | Owner | Evidence |

|---|---|---|---|

| PO Issued | Bilingual PO accepted, chop applied | Buyer/Supplier | Stamped PO PDF |

| Golden Sample Approved | Final sign‑off sample used for mass production | Buyer/QC | Signed sample photo + spec sheet |

| Materials Inbound | All critical components delivered | Supplier | Photos + packing list |

| Production Slot Confirmed | Line and start date booked | Supplier | Planner email/WeChat confirmation |

| Mid‑Production QC | QC at 20–30% completion | Buyer/QC | Report with photos, AQL plan |

| Final QC | QC at 100% before packing | Buyer/QC | Final report |

| Ready Date | Goods ready for pickup | Supplier | Warehouse release note |

| Booking Cut‑off | Carrier deadline for loading | Freight | Booking sheet |

| ETD/ETA | Departure/Arrival | Freight | Carrier schedule |

Fast scripts you can use

- “We will launch on Aug 15. To protect both sides, can we agree: production start July 10, finish July 25, final QC July 26, ready date July 27? We’ll add a 3‑day buffer for any rework.”

- “Please confirm raw material lead time and any subcontractor dependencies that affect July production.”

Logistics impact

- Under FOB, you own space booking; ship dates must match port cut‑offs. Under EXW, pickup timing adds domestic trucking variability. Under DDP, confirm who handles customs and taxes; misalignment creates clearance delays. Choosing the right term changes who bears schedule risk.

Mistake 5: Vague specs, soft contracts, and room for interpretation

Symptoms

- “We thought soft‑touch finish was acceptable.” “We followed the drawing, but your label is different.”

- Corrective action debates instead of shipments.

Why it happens

If your PO lacks technical detail, both sides assume. Sales often drafts in English; production reads Chinese. Nuances get lost.

How to fix it

- Use bilingual documents: Issue a bilingual PO/contract with annexes—drawings, bill of materials, packaging, labeling, testing methods, and AQL sampling plan. Both sides read in their native language.

- Lock the “golden sample”: Approve a physically signed golden sample and reference code in the PO. Store one at factory, one with your QC, one at your warehouse.

- Set change control: Any change in materials, supplier, or process requires written approval and updated pricing/timelines.

What to include in your PO/contract

- Scope: Detailed spec with tolerances, materials, finish, color codes (e.g., Pantone).

- Quality: AQL levels by defect category, test methods, pre‑shipment inspection rights, rework/chargeback terms.

- Packaging and labeling: Inner/outer carton specs, pallet pattern, barcodes, shipping marks, country‑of‑origin, and regulatory labels.

- Logistics: Incoterms (e.g., FOB Shenzhen), agreed ready date, booking responsibilities, penalties for missed windows (or service credits).

- Documentation: Commercial invoice, packing list, HS codes, test reports, compliance certificates.

- Signatures: Legal names, title, and company chop.

Fast scripts you can use

- “We will attach Chinese and English specs and AQL 2.5/4.0. Please confirm production will follow the golden sample marked ‘GOLD‑2024‑07’ and no material substitutions will be made without written approval.”

Practical negotiation checklist you can copy

Before negotiation

- Supplier due diligence: Verify business license, factory scope, and past export records. Ask for production capacity and top three customers’ industries.

- Relationship signal: Share a 6–12 month demand range and critical launch dates.

- Decision map: Identify who approves price, MOQ, and schedule; add them to the meeting.

- Documentation: Prepare bilingual PO/contract templates, spec annexes, AQL plan.

- Logistics plan: Choose Incoterms; map port/airport options; check holiday calendar.

During negotiation

- Protect face: Move criticism to private calls; use solution‑first language.

- Trade value: Exchange steadier orders or faster payment approvals for better unit cost or lower MOQ.

- Lock dates: Confirm production slot, ready date, and QC checkpoints; add buffers.

- Confirm authority: Ask who applies the company chop and who can approve schedule changes.

After negotiation

- Summarize in writing: Send a recap with all numbers, dates, and owners. Request “Confirmed” reply.

- Set a short cadence: 10–15 minute weekly WeChat check‑in with sales + production planner + QC.

- Inspect on schedule: Perform mid‑production and final QC versus the golden sample and AQL.

- Book freight backward: Align factory ready date with carrier cut‑offs; avoid last‑minute air.

Short scripts for common negotiation points

Lowering MOQ

- “We plan 3 releases of 1,000 units each this quarter. If we sign all three POs now, can you set MOQ to 1,000 per release at the 3,000‑unit price?”

Handling a “soft yes”

- “Thank you for the confirmation. To avoid any mix‑up, can you please share the production start date, finish date, and line number?”

Price versus quality trade

- “We can accept a 1.5% higher price if you upgrade the zipper to YKK and commit to AQL 1.5 for criticals. Can you confirm the impact on lead time?”

Lead time around holidays

- “Considering Golden Week, we’ll add a 7‑day buffer. Can you pre‑buy material to protect our slot if we provide a 20% deposit earlier?”

Escalation without loss of face

- “We respect your team’s effort. To solve the delay, could we have a short call with your production manager to find a path together?”

Common red flags and how to respond

- “Don’t worry, we can do any spec.” Response: “Great. Could you share two recent test reports and pictures from your line making similar products?”

- “Price is only valid today.” Response: “We can move fast if we confirm the full package—price, MOQ, lead time, QC plan, and ready date. Can we review all items now?”

- “We will start production tomorrow.” Response: “Please send photos of incoming materials and the production schedule with start/finish dates.”

Tie negotiation to logistics outcomes

- Cost of a soft “OK”: Each week of delay near peak season increases risk of rollovers and higher spot rates. Clear ready dates and buffers protect you.

- FOB vs DDP: Under FOB, you control bookings and visibility; better if you run tight launches. DDP helps small teams but requires careful checks on taxes and compliance to avoid clearance delays.

- Consolidation and MOQ: If MOQ is high, explore multi‑SKU consolidation in one shipment; negotiate combined MOQs at component or color level to keep unit economics healthy.

Summary and next steps

Success with Chinese suppliers is not only about a lower unit price. It is about setting up a working relationship that supports predictable capacity, clear quality, and on‑time logistics. Avoid the five cultural pitfalls—transactional mindset, loss of face, wrong‑level negotiation, deadline push without capacity proof, and vague documentation—and you will see fewer surprises and better margins.

Action steps for your next negotiation

- Share a simple rolling forecast and holiday‑aware launch plan.

- Map decision rights; get the boss/production planner into the call.

- Agree a golden sample, AQL, and bilingual spec annexes; require the company chop.

- Lock production start/finish dates and add 10–20% time buffer; align with carrier cut‑offs.

- Set a weekly 10–15 minute WeChat cadence; escalate privately when needed.

People Also Ask

What is the negotiation culture in China?

Chinese negotiation emphasizes relationship building and trust before hard commitments. Expect a slower pace early as both sides test reliability, protect face, and involve senior decision makers. Agreements stick better once a basic level of friendship and mutual benefit is established, supported by clear specs, dates, and a stamped contract.

What cultural factors should you consider when negotiating with international clients?

Consider relationship expectations, face and formality, communication style, hierarchy and decision rights, and protocol (greetings, gifts, meeting setup). Match your approach to these norms: keep feedback respectful, map who decides, confirm in writing, and adapt meeting size and tone to the counterpart’s culture.

How to negotiate with Chinese people?

Prepare relationship signals (forecast, continuity), protect face with solution‑first language, involve the real decision maker, confirm factory capacity and buffers, and put specifics in bilingual, stamped documents. Use a golden sample and AQL, lock production slots and ready dates, and align logistics with agreed Incoterms to avoid delays and disputes.

-

mianzi: Read to understand the concept of “face” in Chinese business and how to use respectful, indirect language to maintain momentum, avoid stalls, and keep cooperation smooth during feedback and escalation. ↩

-

MOQ: Learn what minimum order quantity means, how it affects unit economics, cash flow, and lead times, and practical tactics to negotiate lower MOQs via forecasts, consolidation, and value trade‑offs. ↩

-

guanxi: Explore how relationship capital drives priority, pricing, and problem‑solving in China, and how to build trust with signals of commitment, reciprocity, and consistent communication. ↩

-

AQL: Understand acceptance quality limits, sampling plans, and defect categories so you can set measurable QC targets, embed them in contracts, and reduce inspection disputes. ↩

-

Incoterms: Clarify responsibilities, risk transfer, and cost allocation across shipping terms (e.g., FOB, EXW, DDP) to select the right term for your launch plan and protect schedule and margins. ↩